Composite materials have revolutionized the automotive industry, offering enhanced performance, improved fuel efficiency, and innovative design possibilities. In this article, we will explore the impact of composite materials on automotive design and performance. From lightweight construction to improved safety features, composite materials have transformed the way vehicles are manufactured and experienced.

Table of Contents

- Understanding Composite Materials

- The Benefits of Composite Materials in Automotive Design

- Lightweight Construction and Fuel Efficiency

- Enhanced Structural Integrity and Safety

- Design Freedom and Aesthetics

- Noise and Vibration Reduction

- Thermal Insulation and Energy Efficiency

- Sustainability and Environmental Considerations

- Challenges and Limitations of Composite Materials

- Future Trends and Innovations

- Conclusion

- FAQs (Frequently Asked Questions)

1. Understanding Composite Materials

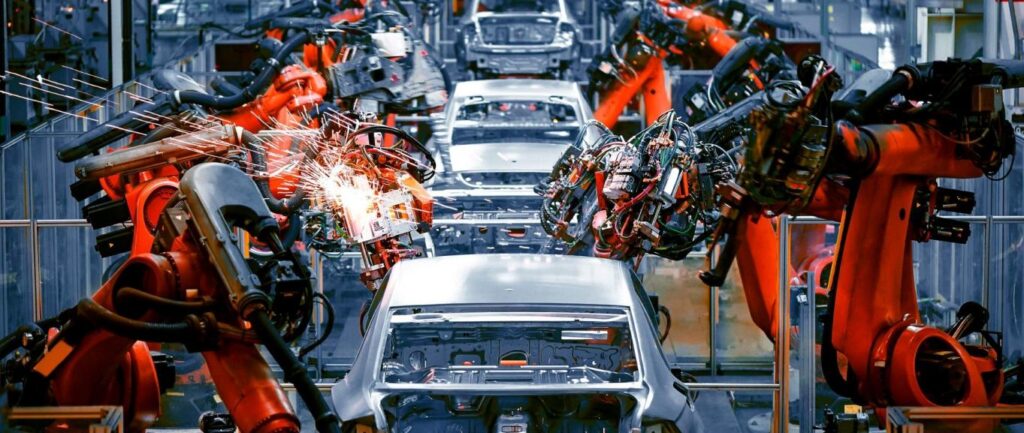

Composite materials are engineered materials made by combining two or more distinct components to create a unique material with superior properties. In the automotive industry, composites are typically composed of a reinforcing fiber, such as carbon fiber or fiberglass, embedded in a polymer matrix.

2. The Benefits of Composite Materials in Automotive Design

Composite materials offer numerous advantages over traditional materials like steel or aluminum. These benefits include:

Lightweight Construction and Fuel Efficiency

Composite materials are significantly lighter than conventional materials, leading to improved fuel efficiency and reduced emissions. By utilizing composites in vehicle manufacturing, automakers can achieve weight reduction without compromising structural integrity.

Enhanced Structural Integrity and Safety

Composite materials possess exceptional strength-to-weight ratios, making them ideal for ensuring structural integrity in vehicles. These materials can absorb and distribute impact forces, improving occupant safety during collisions.

Design Freedom and Aesthetics

Composite materials provide designers with greater freedom to create unique shapes and curves that are difficult to achieve with traditional materials. This versatility allows for more appealing and aerodynamic vehicle designs.

Noise and Vibration Reduction

Composite materials have excellent damping properties, reducing noise and vibrations inside the vehicle cabin. This results in a quieter and more comfortable driving experience.

Thermal Insulation and Energy Efficiency

Composites exhibit excellent thermal insulation properties, reducing heat transfer between the engine and passenger compartment. This improves energy efficiency by reducing the load on the vehicle’s climate control systems.

Sustainability and Environmental Considerations

Composite materials can be recycled, making them more sustainable compared to materials like steel or aluminum. Additionally, their lightweight nature contributes to lower fuel consumption, reducing the overall environmental impact of vehicles.

3. Challenges and Limitations of Composite Materials

While composite materials offer numerous advantages, they also present challenges and limitations that need to be addressed. Some of these include:

- Higher manufacturing costs compared to traditional materials

- Complex production processes requiring specialized equipment and skilled labor

- Limited repairability in case of damage

- Variability in material properties leading to inconsistent performance

4. Future Trends and Innovations

The automotive industry continues to explore and develop new applications for composite materials. Some of the future trends and innovations in this field include:

- Advancements in manufacturing techniques to reduce costs and increase production efficiency

- Integration of smart materials and sensors to enhance safety and performance

- Development of bio-based composites for improved sustainability

- Continued research on nanocomposites to further enhance material properties

Composite materials in the automotive industry have had a profound impact, revolutionizing vehicle design and performance. From lightweight construction and enhanced safety to design freedom and improved fuel efficiency, composites have become a driving force behind innovation in the automotive sector. As the industry continues to push boundaries and explore new possibilities, composite materials will play a pivotal role in shaping the future of automotive engineering.

FAQs (Frequently Asked Questions)

- Q: Are composite materials more expensive than traditional materials? A: Yes, composite materials can be more expensive due to their complex manufacturing processes and specialized equipment requirements.

- Q: Can composite materials be repaired if they get damaged? A: Composite materials can be repaired to some extent, but the process is often more complex compared to traditional materials.

- Q: Are vehicles made entirely of composite materials? A: Currently, most vehicles use a combination of composite materials and traditional materials, striking a balance between performance, cost, and manufacturing feasibility.

- Q: How do composite materials contribute to sustainability? A: Composite materials are lighter, leading to improved fuel efficiency and reduced emissions. They can also be recycled, making them more sustainable compared to materials like steel or aluminum.

- Q: What are some of the latest advancements in composite materials for the automotive industry? A: The industry is exploring advancements such as improved manufacturing techniques, integration of smart materials and sensors, bio-based composites, and research on nanocomposites.