Revolutionise Your Business with the Power of Composites

I. Introduction

Composites have emerged as game-changers in multiple industries, revolutionizing the way businesses operate. These advanced materials offer a wide range of benefits that can enhance product performance, improve efficiency, and drive sustainable practices. In this article, we will explore the significance of composites in various industries and delve into their advantages for businesses seeking to stay ahead in today’s competitive market.

The growing demand for composites is a testament to their effectiveness. Industries such as aerospace, automotive, construction, marine, sports and recreation, and medical have embraced composites for their unique properties and versatility. Whether it’s lightweight aircraft designs, fuel-efficient cars, sustainable buildings, corrosion-resistant ships, high-performance sports equipment, or advanced medical devices, composites have played a vital role in transforming these sectors.

II. Understanding Composites

To fully comprehend the potential of composites, it is essential to understand their definition and composition. Composites are materials made by combining two or more different components with distinct properties to create a superior material with enhanced characteristics. Typically, composites consist of a reinforcing phase, known as the fiber or reinforcement, and a matrix phase, which acts as a binder to hold the fibers together.

Composites come in various types, each with its unique properties and applications. Some common types of composites include:

Fiber-Reinforced Composites: These composites are made by embedding high-strength fibers, such as carbon fibers, glass fibers, or aramid fibers, into a matrix material, such as polymer, metal, or ceramic. The fibers provide strength and stiffness to the composite, while the matrix material holds them in place.

Particle-Reinforced Composites: In this type of composite, particles, such as ceramics, metals, or polymers, are dispersed throughout a matrix material. The particles enhance the mechanical properties of the composite, such as hardness, toughness, or wear resistance.

Structural Composites: Structural composites are designed to bear high loads and provide strength and rigidity to various components. They are widely used in industries like aerospace, automotive, and construction for their lightweight and high-strength characteristics.

Biocomposites: Biocomposites are composed of natural fibers, such as flax, hemp, or bamboo, embedded in a biodegradable polymer matrix. These sustainable composites are gaining popularity in applications where environmental impact is a concern, such as packaging, automotive interiors, and consumer goods.

Understanding the different types of composites allows businesses to identify the most suitable material for their specific requirements, ensuring optimal performance and cost-effectiveness.

III. Applications of Composites in Industries

Composites have become a driving force behind innovation and progress in a wide range of industries. Let’s explore some of the key sectors that have embraced the remarkable capabilities of composites, revolutionizing their products, and achieving significant advancements.

A. Aerospace Industry

The aerospace industry has been at the forefront of utilizing composites to transform aircraft design and performance. By incorporating composite materials, aircraft manufacturers have been able to achieve lightweight structures without compromising on strength or safety. Composites offer a high strength-to-weight ratio, allowing for fuel-efficient aircraft designs that consume less energy during flight. Moreover, composites provide exceptional resistance to corrosion, fatigue, and extreme temperatures, ensuring enhanced durability and longevity. With composites, the aerospace industry has witnessed improved fuel efficiency, reduced maintenance costs, and increased passenger safety.

B. Automotive Industry

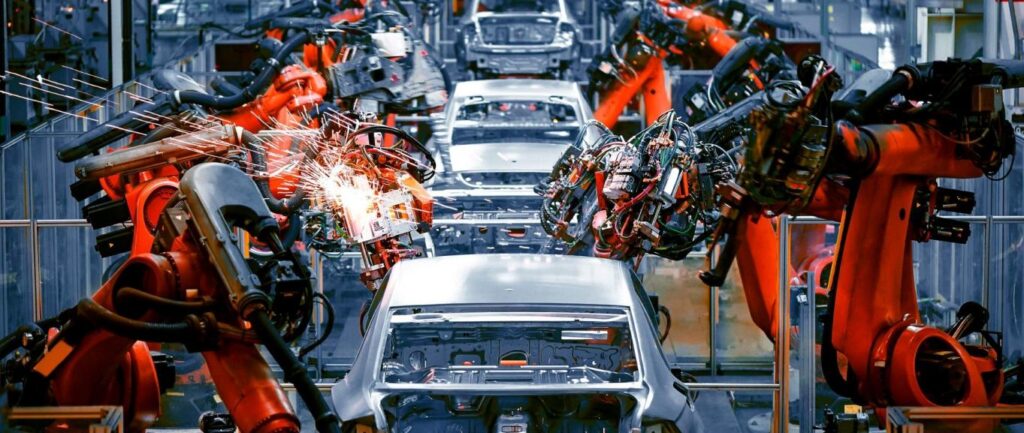

In an era of environmental consciousness, the automotive industry has turned to composites to address the challenges of fuel efficiency and emissions reduction. Composites offer significant weight savings compared to traditional materials, such as steel or aluminum, without compromising on structural integrity. By incorporating composites into vehicle components, manufacturers have achieved improved fuel efficiency and reduced emissions. Additionally, composites enhance safety by providing excellent crash absorption properties and better energy dissipation during collisions. The automotive industry has also witnessed advancements in electric vehicle (EV) technology, where composites help reduce the overall weight of the vehicle, extending the range and optimizing battery performance.

C. Construction Industry

The construction industry is increasingly embracing composites for sustainable and energy-efficient building solutions. Composites offer excellent thermal insulation properties, reducing energy consumption for heating and cooling. Additionally, they provide superior resistance to environmental factors such as moisture, corrosion, and UV radiation, ensuring long-term durability and minimal maintenance requirements. Composites also enable the construction of complex shapes and structures, facilitating innovative architectural designs. From bridge components to cladding systems and roofing materials, composites have proven to be a game-changer in the construction industry, enabling efficient, sustainable, and visually appealing structures.

D. Marine Industry

In the marine industry, composites have brought about significant advancements in shipbuilding and naval architecture. With their lightweight properties and high resistance to corrosion, composites offer a superior alternative to traditional materials like steel or aluminum. By utilizing composites, shipbuilders have been able to construct lighter vessels that require less energy to propel, leading to improved fuel efficiency and reduced operational costs. Additionally, composites provide enhanced performance characteristics, including better maneuverability, increased speed, and reduced noise and vibration levels. From leisure boats to commercial ships, composites have revolutionized the marine industry, offering durable and efficient solutions.

E. Sports and Recreation Industry

Composites play a vital role in the sports and recreation industry, driving innovation and pushing the boundaries of performance. From professional sports equipment to recreational gear, composites offer exceptional strength, stiffness, and impact resistance, enabling the creation of high-performance products. Tennis rackets, golf clubs, bicycles, snowboards, and skis are just a few examples of sporting equipment that have benefited from the use of composites. The lightweight nature of composites allows athletes to exert less energy during activities, leading to improved endurance and performance. Furthermore, composites provide safety features such as shock absorption and vibration damping, minimizing the risk of injuries.

F. Medical Industry

The medical industry has embraced composites to develop advanced prosthetics, orthotics, and medical devices. Composites offer a unique combination of biocompatibility, durability, and customization, making them ideal for applications in the healthcare sector. Prosthetic limbs made with composites provide enhanced functionality, comfort, and aesthetics, improving the quality of life for individuals with limb loss. Composites also find application in orthotic devices, such as braces and supports, offering lightweight solutions that provide optimal support and mobility. Furthermore, composites are used in the production of durable and biocompatible medical implants, such as bone substitutes and dental components.

The applications of composites in these industries represent just a fraction of the possibilities and opportunities that composites offer. As businesses continue to recognize the advantages of composites, we can expect further breakthroughs and transformative changes across various sectors.

IV. Advantages of Composites for Businesses

Composites offer a myriad of advantages that can revolutionize businesses across various industries. From lightweight and strength to design flexibility and environmental sustainability, the utilization of composites can drive significant improvements in product performance, operational efficiency, and overall success. Let’s explore the key advantages that composites bring to businesses.

A. Lightweight and Strength

One of the most notable advantages of composites is their exceptional strength-to-weight ratio. Composites are lightweight materials that offer impressive structural integrity and durability. By incorporating composites into product design, businesses can achieve weight reduction without compromising on strength and performance. The reduced weight brings several benefits, such as improved fuel efficiency in transportation, enhanced maneuverability in aerospace and marine applications, and increased portability in various industries. Moreover, the use of composites in load-bearing structures and components ensures superior strength, resistance to deformation, and extended product longevity.

B. Design Flexibility

Composites provide businesses with unparalleled design flexibility, allowing for the creation of complex shapes and structures that may be challenging or impossible to achieve with traditional materials. The versatility of composites enables businesses to push the boundaries of innovation and differentiate their products in the market. Whether it’s sleek and aerodynamic aircraft wings, curvaceous automotive body panels, or intricate architectural elements, composites offer the freedom to bring imaginative designs to life. This design flexibility empowers businesses to meet the evolving demands and preferences of customers, leading to unique and visually appealing products that stand out from the competition.

C. Corrosion Resistance

Corrosion can be a significant challenge in various industries, leading to costly repairs, maintenance, and premature product failure. Composites excel in their resistance to corrosion, making them an ideal choice for businesses operating in corrosive environments. Unlike metals, composites do not rust or degrade when exposed to moisture, chemicals, or harsh weather conditions. This corrosion resistance translates into extended product lifespan, reduced maintenance costs, and enhanced reliability. By utilizing composites, businesses can deliver durable and long-lasting solutions that withstand the test of time, even in challenging operating conditions.

D. Cost-effectiveness

While composites may have higher upfront costs compared to traditional materials, they offer compelling cost-effectiveness in the long run. The lightweight nature of composites leads to reduced transportation costs, as lighter products require less energy for shipping and logistics. Additionally, the inherent durability and resistance of composites contribute to lower maintenance and replacement expenses over the product’s lifecycle. Furthermore, composites enable improved manufacturing efficiency through simplified processes, such as moldability and automation, reducing production time and costs. By leveraging the cost-effective nature of composites, businesses can optimize their operations and improve their bottom line.

E. Environmental Sustainability

As businesses increasingly prioritize sustainability, composites offer significant advantages in reducing the environmental impact. Composites contribute to a lower carbon footprint due to their lightweight nature, which translates into reduced energy consumption during transportation and use. Furthermore, composites can be recycled and reused, minimizing waste and promoting a circular economy. The production processes of composites also tend to be more eco-friendly compared to traditional manufacturing methods, as they consume less energy and produce fewer greenhouse gas emissions. By adopting composites, businesses can align with sustainable practices and enhance their corporate social responsibility.

The advantages of composites for businesses are undeniable. From lightweight and strength to design flexibility, corrosion resistance, cost-effectiveness, and environmental sustainability, composites empower businesses to innovate, improve product performance, and gain a competitive edge in the market. In the next section, we will explore the implementation strategies and considerations for integrating composites into your business operations.

V. Implementing Composites in Your Business

Composites offer a multitude of benefits for businesses across industries, ranging from enhanced product performance to cost savings and sustainability. However, effectively integrating composites into your business requires careful planning and strategic implementation. In this section, we will explore key steps to consider when incorporating composites into your operations.

A. Research and Development

Research and development form the foundation for successful implementation of composites in your business. Begin by understanding the specific needs and challenges within your industry. Identify areas where composites can bring significant improvements and add value to your products or processes. This understanding will guide your decision-making and ensure that you focus on the most relevant applications of composites within your business.

Collaboration with composite experts is crucial during the research and development phase. Engage with specialists who possess deep knowledge and experience in working with composites. They can provide valuable insights, offer technical expertise, and help you navigate the complexities of composite materials. By leveraging their expertise, you can make informed decisions and optimize the integration of composites in your business.

B. Material Selection

Choosing the right composite materials is a critical aspect of successful implementation. Assess different composite options available in the market and evaluate their suitability for your specific requirements. Consider factors such as material properties, performance characteristics, durability, and cost.

Collaborate with composite suppliers and manufacturers who can guide you through the material selection process. They can provide samples, technical data, and expertise to help you make informed decisions. Additionally, consider the long-term availability and reliability of the chosen composite materials to ensure a sustainable supply chain for your business.

C. Design and Engineering

Integrating composites into your product design and engineering processes is a transformative step. Work closely with design and engineering teams to identify opportunities for incorporating composites. Leverage the design flexibility offered by composites to create innovative and efficient products.

During the design phase, optimize for performance and efficiency. Understand the unique properties of composites, such as their strength, lightweight nature, and resistance to corrosion. Tailor your designs to leverage these properties and maximize the benefits offered by composites.

Utilize advanced simulation and modeling tools to analyze the behavior of composites under different conditions. This will help you refine your designs, ensure structural integrity, and enhance performance. Collaborate with engineering consultants and specialists to validate your design choices and ensure compliance with industry standards and regulations.

D. Manufacturing and Production

Selecting appropriate manufacturing processes is crucial for successful implementation of composites. Each composite material may require specific manufacturing techniques, such as resin infusion, filament winding, or compression molding. Collaborate with composite manufacturers and experts to determine the most suitable manufacturing processes for your specific applications.

Ensure that your manufacturing facilities are equipped with the necessary infrastructure and equipment to handle composites. Implement quality control measures and adhere to industry standards to maintain consistency and reliability in the production process. Regular inspections and testing will help identify any issues and ensure that the manufactured composites meet the required specifications.

E. Training and Workforce Development

Equipping your employees with composite expertise is vital for seamless integration and successful implementation. Invest in training programs to enhance the knowledge and skills of your workforce in working with composites. Collaborate with educational institutions, industry associations, and training providers to access specialized composite training programs.

Training should cover various aspects, including composite materials, manufacturing processes, design considerations, safety protocols, and best practices. By fostering a culture of continuous learning and development, you empower your employees to effectively utilize composites and contribute to the success of your business.

Implement robust safety protocols and ensure compliance with occupational health and safety regulations. Provide appropriate personal protective equipment (PPE) and create a safe working environment for employees handling composites. Regularly review and update safety guidelines to align with evolving industry standards.

By following these steps, businesses can successfully implement composites and unlock their full potential. Composites have the power to revolutionize your products, improve operational efficiency, and contribute to a sustainable future.

VI. Case Studies: Success Stories with Composites

Composites have proven to be a game-changer for numerous businesses across industries, revolutionizing their products, processes, and overall performance. In this section, we will delve into inspiring case studies that highlight the remarkable benefits achieved by businesses through the strategic implementation of composites.

1. Aerospace Industry: Lighter, Stronger, and Fuel-Efficient Aircraft Designs

Leading aircraft manufacturers have harnessed the power of composites to redefine aviation. Companies like Boeing and Airbus have successfully integrated composite materials into their aircraft designs, resulting in lighter and more fuel-efficient planes. The Boeing 787 Dreamliner, for instance, incorporates composites extensively, reducing weight and enabling improved fuel economy. These advancements have not only lowered operational costs but have also enhanced the safety and performance of aircraft.

2. Automotive Industry: Enhancing Efficiency and Safety

Automakers have embraced composites to make vehicles more fuel-efficient, structurally robust, and environmentally friendly. Tesla, the electric vehicle pioneer, leverages composites to create lightweight and aerodynamic bodies for its electric cars. The use of composites in components like body panels and chassis enhances energy efficiency, extends the driving range, and reduces emissions. Moreover, composites contribute to improved crash safety and structural integrity, making vehicles safer for passengers.

3. Construction Industry: Sustainable and Resilient Building Solutions

The construction industry has embraced composites for sustainable and energy-efficient building solutions. Companies like Owens Corning and Kingspan utilize composite-based insulation materials to enhance energy efficiency and reduce heat transfer in buildings. These innovative solutions not only improve the thermal performance of structures but also contribute to reduced energy consumption and lower carbon footprints. Composites are also valued for their durability and resistance to environmental factors, ensuring long-lasting and resilient building materials.

4. Marine Industry: Lightweight and Corrosion-Resistant Shipbuilding

In the marine industry, composites offer a wide range of advantages for shipbuilding and maritime applications. Companies like Bénéteau Group and Sunseeker International utilize composites to construct lightweight and corrosion-resistant hulls for yachts and boats. By incorporating composites, these manufacturers achieve increased fuel efficiency, improved speed, and enhanced performance on water. Furthermore, composites provide excellent resistance to water-induced degradation, resulting in longer vessel lifespans and reduced maintenance costs.

5. Sports and Recreation Industry: High Performance and Enhanced Safety

Composites play a pivotal role in the sports and recreation industry, enabling the creation of high-performance equipment and gear. Carbon fiber composites are extensively used in the manufacturing of bicycles, tennis rackets, golf clubs, and skis. By utilizing composites, companies like Specialized and Callaway Golf achieve lighter weight, increased strength, and enhanced performance characteristics in their products. Athletes benefit from improved maneuverability, increased power transfer, and reduced fatigue, leading to better performance and safety.

6. Medical Industry: Advanced Prosthetics and Biocompatible Devices

The medical industry has embraced composites to advance prosthetics, orthotics, and medical devices. Carbon fiber composites are widely utilized to create lightweight and durable prosthetic limbs that offer improved mobility and comfort. Additionally, composites provide excellent biocompatibility, making them suitable for implants and medical instruments. Companies like Össur and Medtronic have leveraged composites to enhance patient care, enabling individuals to regain mobility and improving the quality of life.

These case studies highlight the transformative power of composites across various industries. Businesses that strategically implement composites gain a competitive edge by improving performance, reducing costs, and promoting sustainability. By learning from these success stories, your business can explore innovative ways to harness the potential of composites and revolutionize your industry.

VII. Overcoming Challenges in Implementing Composites

Integrating composites into your business operations can bring about transformative benefits, but it is not without its challenges. In this section, we will explore key hurdles that businesses may encounter when implementing composites and provide valuable insights on how to overcome them.

A. Cost and Investment

Evaluating long-term cost savings: While composites may require a higher upfront investment compared to traditional materials, it is crucial to assess the long-term cost savings they offer. Consider factors such as improved product performance, increased durability, reduced maintenance costs, and enhanced energy efficiency. Conduct a comprehensive cost-benefit analysis to determine the potential return on investment (ROI) over time.

Securing funding and financial resources: Implementing composites may require significant financial resources. Seek funding options such as grants, loans, or venture capital investment. Present a compelling business case that highlights the benefits of composites in terms of market competitiveness, improved product quality, and sustainability. Explore partnerships or collaborations with industry associations or government programs that support the adoption of innovative technologies.

B. Regulatory and Certification Requirements

Navigating industry-specific regulations: Different industries have specific regulations and standards governing the use of composites. It is essential to familiarize yourself with these requirements to ensure compliance. Engage with regulatory bodies, industry associations, or consultants who specialize in compliance to understand the regulations that apply to your sector. Stay updated on any changes or advancements in the regulatory landscape.

Ensuring compliance and certifications: Composites may need to meet certain certifications to guarantee their quality, safety, and performance. Work closely with certification agencies to understand the necessary steps and requirements for obtaining certifications relevant to your industry. This could include certifications for fire resistance, structural integrity, or environmental sustainability. Maintain thorough documentation and quality control processes to demonstrate compliance.

C. Knowledge and Skills Gap

Bridging the expertise gap in composites: Implementing composites requires specialized knowledge and skills. Assess the existing expertise within your organization and identify any gaps. Invest in training programs and workshops to upskill employees in composite design, engineering, manufacturing, and quality control. Encourage cross-functional collaboration and knowledge sharing to foster a culture of continuous learning.

Collaborating with educational institutions and training programs: Forge partnerships with educational institutions, research centers, or industry experts specializing in composites. Collaborate on research and development projects, internships, or apprenticeship programs to access the latest advancements and build a pipeline of skilled professionals. Engage with composite-focused training programs to ensure your workforce stays updated with the latest techniques and best practices.

By addressing these challenges head-on, businesses can pave the way for successful implementation of composites. Strategic planning, thorough evaluation, and collaboration with relevant stakeholders are key to overcoming hurdles and unlocking the full potential of composites in your industry.

VIII. Future Trends and Innovations in Composites

Composites have revolutionized various industries with their unique properties and advantages. As technology continues to advance, new trends and innovations are emerging, pushing the boundaries of what composites can achieve. In this section, we will explore some of the exciting developments that are shaping the future of composites.

1. Advanced Materials and Nanotechnology

The development of advanced materials and nanotechnology is driving significant advancements in composites. Researchers are exploring nanomaterials, such as carbon nanotubes and graphene, to enhance the mechanical, thermal, and electrical properties of composites. These nanoscale reinforcements offer unprecedented strength, lightweight characteristics, and exceptional conductivity, opening up new possibilities for applications in aerospace, automotive, and electronics industries.

2. Sustainable Composites

Sustainability is becoming an increasingly important aspect of material selection and manufacturing processes. The future of composites lies in the development of sustainable alternatives, such as bio-based resins and recycled reinforcement materials. These eco-friendly composites reduce reliance on fossil fuels, lower carbon emissions, and promote a circular economy. Companies are investing in research and technologies that enable the production of high-performance, sustainable composites, aligning with the growing demand for environmentally friendly solutions.

3. Additive Manufacturing (3D Printing)

Additive manufacturing, or 3D printing, is transforming the way composites are produced. This technology allows for the creation of complex geometries and customized structures, opening up new design possibilities. By depositing composite materials layer by layer, 3D printing enables efficient use of materials, reduces waste, and accelerates production. As additive manufacturing processes continue to improve, we can expect to see increased adoption of composites in various industries, including aerospace, automotive, and medical.

4. Multifunctional Composites

The future of composites lies in their ability to integrate multiple functionalities into a single material. Researchers are exploring the incorporation of sensors, actuators, and energy storage components within composites. These multifunctional composites can monitor structural health, self-repair damage, or even harvest energy from the environment. By combining structural performance with additional functionalities, composites will enable the development of smart, adaptive structures with enhanced efficiency and safety.

5. Digital Twin and Simulation

Digital twin technology, combined with advanced simulation software, is revolutionizing the design and optimization of composite structures. Digital twin refers to a virtual replica of a physical asset or system that can simulate real-time behavior and performance. By leveraging data from sensors embedded within composites, manufacturers can monitor and analyze their products’ performance throughout their lifecycle. This information can be used to optimize designs, predict maintenance needs, and improve overall efficiency.

6. Automation and Robotics

Automation and robotics are increasingly being utilized in composite manufacturing processes. Robotic systems can handle repetitive and labor-intensive tasks with precision and efficiency, reducing production time and costs. Automated processes, such as automated fiber placement and tape laying, ensure consistent quality and eliminate human error. As robotics and automation technologies continue to advance, the adoption of composites in mass production industries will become more feasible.

The future of composites is bright and full of possibilities. As these trends and innovations continue to evolve, businesses must stay abreast of the latest developments and adapt their strategies accordingly. Embracing emerging technologies, exploring sustainable options, and investing in research and development will be key to harnessing the full potential of composites in the years to come.

IX. Summary and Key Takeaways

Throughout this article, we have explored the remarkable potential of composites in revolutionizing businesses across various industries. Composites, which are materials made by combining two or more distinct components, offer a wide range of advantages that can enhance product performance, improve sustainability, and drive cost-effectiveness. Let’s summarize the key takeaways from our exploration:

Composites offer exceptional properties: Composites possess a unique combination of properties, including lightweightness, strength, durability, and corrosion resistance. These characteristics make them highly desirable for industries such as aerospace, automotive, construction, marine, sports, recreation, and healthcare.

Applications in diverse industries: Composites find applications in numerous industries. In aerospace, they enable fuel-efficient aircraft designs and enhanced safety features. The automotive industry benefits from improved fuel efficiency, structural integrity, and safety. Composites provide sustainable and energy-efficient building solutions in construction. In the marine industry, they offer lightweight and corrosion-resistant shipbuilding capabilities. Sports and recreation benefit from high-performance equipment, while the medical industry benefits from advanced prosthetics and durable medical devices.

Advantages for businesses: The use of composites brings several advantages to businesses. Their lightweight nature reduces transportation costs and improves product performance and longevity. Composites offer design flexibility, allowing for complex shapes and customizable aesthetics. Their corrosion resistance leads to longer product lifespans and reduced maintenance costs. Composites can also be cost-effective, improving manufacturing efficiency and lowering production and operational expenses. Lastly, they contribute to environmental sustainability by reducing the carbon footprint and promoting recyclability.

Implementing composites in your business: To successfully implement composites in your business, consider the following steps:

Research and Development: Understand your industry’s needs and challenges and collaborate with composite experts to identify opportunities for implementation.

Material Selection: Assess different composite options based on their properties and requirements, considering factors such as strength, durability, and sustainability.

Design and Engineering: Integrate composites into product design, optimizing for performance and efficiency. Leverage the design flexibility of composites to create innovative solutions.

Manufacturing and Production: Choose appropriate manufacturing processes that ensure quality control and adhere to industry standards. Implement rigorous testing and inspection procedures.

Training and Workforce Development: Equip your employees with the necessary composite expertise. Implement safety protocols and best practices to ensure a safe working environment.

Success stories with composites: Several businesses have achieved significant benefits by incorporating composites into their operations. Case studies highlight the successful utilization of composites in various industries, showcasing the transformative impact they can have on products, performance, and market competitiveness.

Overcoming challenges: Implementing composites comes with challenges that businesses must address. These challenges include managing cost and investment, navigating regulatory and certification requirements, and bridging the knowledge and skills gap. Collaboration with educational institutions and training programs can help bridge the expertise gap in composites.

Future trends and innovations: The future of composites is promising. Advancements in advanced materials, nanotechnology, sustainable composites, additive manufacturing, multifunctionality, digital twin technology, and automation are set to shape the industry. Keeping up with these trends and embracing emerging technologies will be crucial for businesses to stay competitive.

In conclusion, composites offer immense potential to revolutionize businesses across industries. By understanding the applications, advantages, implementation strategies, and future trends, businesses can harness the power of composites to drive innovation, sustainability, and growth. Embrace the possibilities that composites offer and position your business at the forefront of technological advancements.

X. FAQs about Composites in Business

As composites gain prominence in various industries, businesses are eager to understand the implications and benefits of incorporating these materials into their operations. In this section, we will address some frequently asked questions about composites in business to provide clarity and insights.

1. What are the primary advantages of composites in the manufacturing industry?

Composites offer several advantages in the manufacturing industry. These include:

Lightweight and Strength: Composites are significantly lighter than traditional materials like metals, reducing transportation costs and improving fuel efficiency. Despite their low weight, composites possess excellent strength and structural integrity, making them ideal for applications where weight reduction is critical.

Design Flexibility: Composites offer remarkable design flexibility, allowing businesses to create complex shapes and structures. This enables innovative product designs and customized aesthetics, giving a competitive edge in the market.

Corrosion Resistance: Unlike metals, composites are highly resistant to corrosion, making them suitable for applications in harsh environments. This characteristic extends the lifespan of products, reduces maintenance costs, and enhances durability.

Cost-effectiveness: Although composites may have higher upfront costs, they can lead to long-term cost savings. Composites improve manufacturing efficiency, lower production and operational expenses, and reduce maintenance and replacement costs over time.

Environmental Sustainability: Composites contribute to environmental sustainability by reducing the carbon footprint. They are recyclable, and the production processes can be eco-friendly, aligning with the growing demand for sustainable practices.

2. How can composites improve the sustainability of construction projects?

Composites offer several sustainability benefits to construction projects, including:

Energy Efficiency: Composites provide excellent thermal insulation, reducing the reliance on heating and cooling systems. This improves energy efficiency and lowers operational costs.

Sustainable Materials: Some composites are made from renewable or recycled materials, reducing the demand for virgin resources. Bio-based resins and recycled reinforcement materials contribute to a circular economy and minimize environmental impact.

Durability and Resistance: Composites have superior resistance to environmental factors such as moisture, chemicals, and UV radiation. This enhances the lifespan of construction projects, reducing the need for frequent repairs or replacements.

Lightweight Construction: Composites’ lightweight nature reduces the load on foundations and structures, allowing for more efficient use of materials. This can lead to reduced material consumption and construction waste.

3. What challenges should businesses anticipate when adopting composites?

Businesses may face the following challenges when adopting composites:

Cost and Investment: Upfront costs associated with composites can be higher than traditional materials. However, businesses should evaluate the long-term cost savings, improved performance, and durability that composites offer.

Regulatory and Certification Requirements: Different industries have specific regulations and certification requirements for composites. Navigating these requirements can be complex, and businesses must ensure compliance to meet industry standards and ensure product quality.

Knowledge and Skills Gap: Working with composites requires specialized knowledge and expertise. Businesses may face challenges in finding skilled professionals. Collaborating with educational institutions, training programs, and industry experts can bridge the knowledge gap and build a competent workforce.

4. Are there any limitations or drawbacks to using composites?

While composites offer numerous advantages, they also have some limitations to consider:

Cost: As mentioned earlier, composites can have higher upfront costs compared to traditional materials. However, businesses should assess the long-term cost benefits and return on investment.

Material Variability: The properties of composites can vary based on the manufacturing processes and materials used. Consistency in material properties and quality control is crucial to ensure desired performance.

Recycling and Disposal: While composites are recyclable, the recycling infrastructure and processes are still developing. Proper recycling and disposal methods need to be established to manage end-of-life composites effectively.

Specialized Manufacturing: Composites often require specialized manufacturing processes and equipment. Businesses may need to invest in training and infrastructure to accommodate composite production.

By understanding these considerations, businesses can make informed decisions and overcome challenges to successfully implement composites in their operations.

In conclusion, composites offer compelling advantages for businesses across industries. Their lightweight nature, design flexibility, durability, and sustainability benefits make them a valuable choice. While challenges such as cost, regulatory compliance, and knowledge gaps exist, these can be overcome through careful planning, collaboration, and investment in expertise. By embracing composites, businesses can unlock new opportunities, drive innovation, and position themselves for success in an ever-evolving market. We have now explored the fundamentals, advantages, implementation strategies, success stories, and future trends of composites. We hope this comprehensive guide has provided valuable insights for your business journey.

Table of content:

I. Introduction

– Definition and significance of composites in various industries

– Growing demand for composites and their advantages

II. Understanding Composites

– Definition and composition of composites

– Different types of composite materials

III. Applications of Composites in Industries

A. Aerospace Industry

1. Lightweight and fuel-efficient aircraft designs

2. Enhanced performance and safety features

B. Automotive Industry

1. Improving fuel efficiency and reducing emissions

2. Strengthening structural integrity and safety

C. Construction Industry

1. Sustainable and energy-efficient building solutions

2. Durability and resistance to environmental factors

D. Marine Industry

1. Lightweight and corrosion-resistant shipbuilding

2. Improved speed and performance on water

E. Sports and Recreation Industry

1. High-performance equipment and gear

2. Enhancing athlete performance and safety

F. Medical Industry

1. Advanced prosthetics and orthotics

2. Biocompatible and durable medical devices

IV. Advantages of Composites for Businesses

A. Lightweight and Strength

1. Reducing transportation costs

2. Enhancing product performance and longevity

B. Design Flexibility

1. Creating complex shapes and structures

2. Customizable aesthetics

C. Corrosion Resistance

1. Longer lifespan of products

2. Reduced maintenance and replacement costs

D. Cost-effectiveness

1. Improving manufacturing efficiency

2. Lowering production and operational expenses

E. Environmental Sustainability

1. Reduced carbon footprint

2. Recyclability and eco-friendly production processes

V. Implementing Composites in Your Business

A. Research and Development

1. Understanding your industry’s needs and challenges

2. Collaborating with composite experts

B. Material Selection

1. Assessing different composite options

2. Considering material properties and requirements

C. Design and Engineering

1. Integrating composites into product design

2. Optimizing for performance and efficiency

D. Manufacturing and Production

1. Choosing appropriate manufacturing processes

2. Ensuring quality control and standards

E. Training and Workforce Development

1. Equipping employees with composite expertise

2. Implementing safety protocols and best practices

VI. Case Studies: Success Stories with Composites

– Highlighting businesses that achieved significant benefits using composites

VII. Overcoming Challenges in Implementing Composites

A. Cost and Investment

1. Evaluating long-term cost savings

2. Securing funding and financial resources

B. Regulatory and Certification Requirements

1. Navigating industry-specific regulations

2. Ensuring compliance and certifications

C. Knowledge and Skills Gap

1. Bridging the expertise gap in composites

2. Collaborating with educational institutions and training programs

D. Supply Chain Considerations

1. Sourcing reliable composite materials

2. Managing logistics and inventory

VIII. Future Trends and Innovations in Composites

– Exploring emerging technologies and breakthroughs

IX. Summary and Key Takeaways

– Recap of the benefits and potential of composites for businesses

X. FAQs about Composites in Business

1. What are the primary advantages of composites in the manufacturing industry?

2. How can composites improve the sustainability of construction projects?

3. What challenges should businesses anticipate when adopting composites?

4. Are there any limitations or drawbacks to using composites?

5. What trends can we expect to see in the composites industry in the near future?