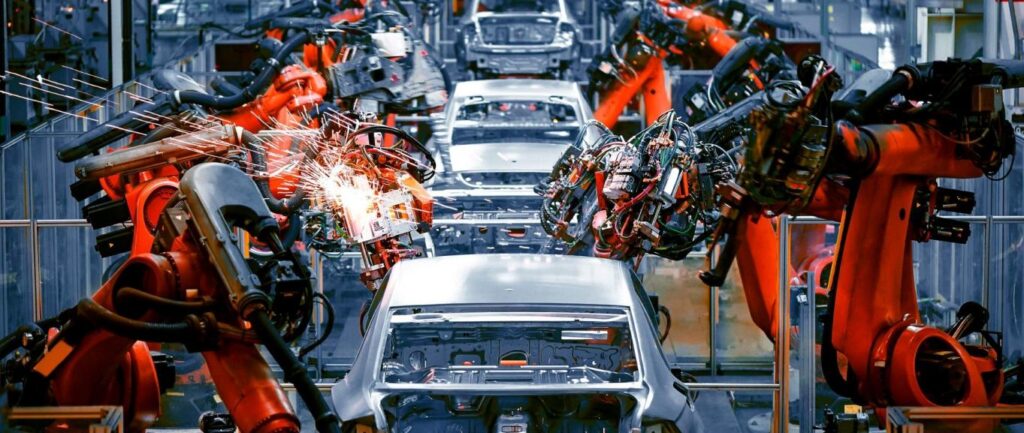

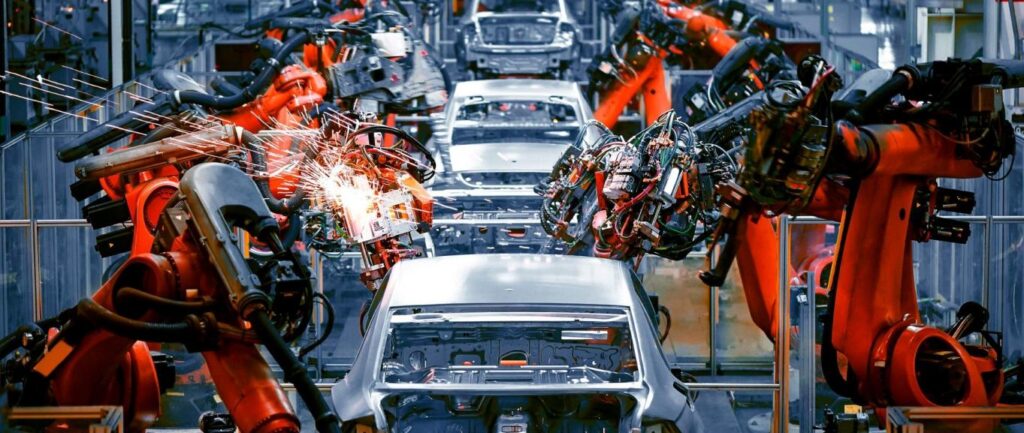

Revolutionising the Automotive Industry: The Power of Composite Materials

In today’s fast-paced world, the automotive industry is constantly seeking innovative solutions to enhance performance, fuel efficiency, and safety while reducing weight and environmental impact. One such solution that has gained significant attention is the use of composite materials. These advanced materials offer a multitude of benefits that can revolutionise the way we design and manufacture vehicles. In this article, we will explore how composite materials can help improve the automotive industry and pave the way for a greener, more efficient future.

Lighter, Stronger, and More Fuel-Efficient Vehicles

Composite materials, such as carbon fiber reinforced polymers (CFRP) and fiberglass composites, have an exceptional strength-to-weight ratio. By integrating these materials into vehicle structures, automakers can significantly reduce weight without compromising structural integrity. Lighter vehicles require less energy to propel, leading to improved fuel efficiency and reduced emissions. Additionally, the strength and stiffness of composites enhance overall vehicle safety by providing better crash resistance and impact absorption capabilities.

Design Freedom and Flexibility

Unlike traditional materials like steel or aluminum, composites offer unparalleled design freedom and flexibility. These materials can be molded into complex shapes and integrated into various vehicle components, including body panels, chassis, and interior parts. By utilizing composite materials, designers can create sleeker, aerodynamic designs that reduce drag, improve performance, and enhance aesthetics. Moreover, the ability to customize composite structures allows for tailored solutions to meet specific performance requirements.

Enhanced Durability and Corrosion Resistance

One significant advantage of composite materials in the automotive industry is their exceptional durability and corrosion resistance. Unlike metals, composites are impervious to rust, which is a common issue in conventional automobiles. This characteristic significantly extends the lifespan of composite components, reducing maintenance costs and increasing overall vehicle reliability. Moreover, composites have excellent resistance to chemicals, UV radiation, and temperature fluctuations, making them ideal for various environmental conditions.

Improved Acoustic and Vibrational Performance

Noise and vibrations are common challenges in the automotive industry. However, composite materials can effectively address these issues. By utilizing composites in vehicle structures, manufacturers can achieve better acoustic insulation and vibration dampening, resulting in a quieter and more comfortable ride. This improvement in passenger comfort is particularly important for electric vehicles, where reduced engine noise makes the cabin environment even more critical.

Environmental Sustainability

The automotive industry is increasingly focusing on reducing its carbon footprint and promoting environmental sustainability. Composite materials play a vital role in achieving these goals. As mentioned earlier, lighter vehicles result in improved fuel efficiency and reduced emissions. Additionally, composite materials are recyclable and have a lower carbon footprint compared to traditional materials. The ability to recycle composites not only reduces waste but also allows for the recovery of valuable resources, making them an eco-friendly choice for the automotive industry.

Composite materials have the potential to revolutionise the automotive industry, offering numerous advantages such as weight reduction, improved fuel efficiency, enhanced safety, and design flexibility. As the industry continues to evolve, automakers are increasingly embracing composites to create vehicles that are lighter, stronger, and more environmentally friendly. By harnessing the power of composite materials, the automotive industry can push the boundaries of innovation, delivering sustainable transportation solutions that meet the demands of the future. So, let us embark on this journey towards a greener and more efficient automotive landscape powered by composite materials.